Sophisticated, Reliable Construction

Kawashima’s Horizontal Packaging Machine

Kawashima’s horizontal packaging machine is pursuing for high usability.

It is hygienic and easy-maintenance structure which has been used by many customers.

Capture0001A-2_21090626_CMYK-1-500x500.jpg)

Product category:Horizontal Packaging Machine

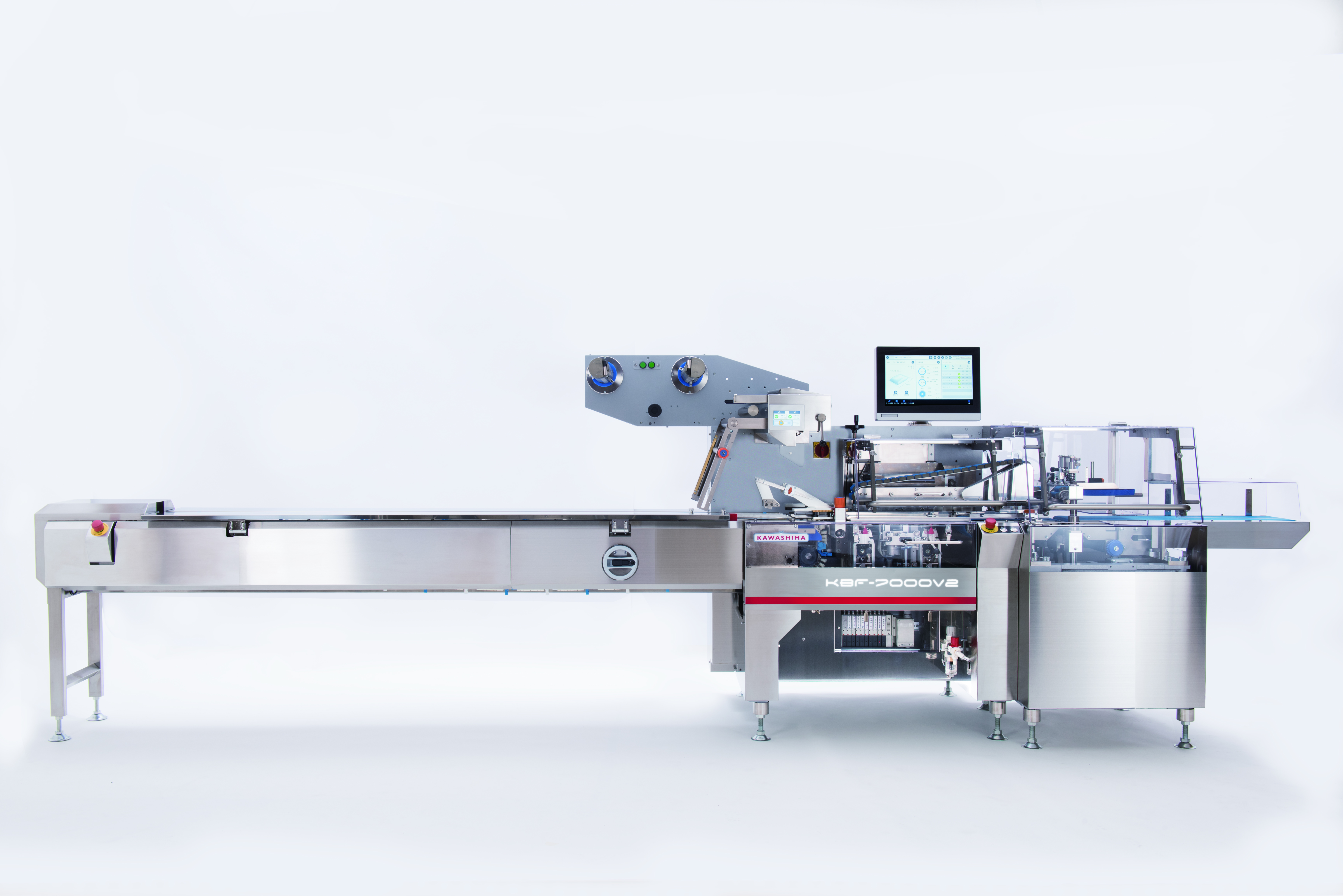

KBF-7000V2 Horizontal Form Fill Seal Machine

We deliver reliable products based on our abundant experience and ideas.

Product features

-

01

Improvement in production efficiency

Evolution in "multi-motion"Our unique "multi-motion" mechanism has further evolved to achieve a maximum packaging capacity of 270 bpm.

The optimum setting of seal pressure and seal timing for each product has been simplified. -

02

Improvement in work efficiency

Prevents operator adjustment errorsThe most important tension arm data has been digitized.

The adjustment part has a higher reproducibility by checking the numerical values using the scale. -

03

Pre-announcement by predict function

Reduce downtime with maintenance forecastsWhen maintenance is required, the machine notifies you the condition in advance. By notifying the necessary parts in advance, sudden machine stoppage can be prevented.

-

04

Enhancing self-judgment by machine

Automatically calculate various data at the time of new product registrationBy inputting film dimensions and product dimensions, the machine calculates the former width / height, tension angle and distance, automatically which are often dependent on operator's experience.

Defective discharge shifts are also calculated automatically, which reduces operator's setting work.

Purpose

Cookies, sauces, biscuits, confectionery breads, chocolates (including chocolates), candies, ramney, roasted rice cake, oaks, bunkers, tempura, frozen hamburgers, frozen gyosa, frozen shomei, vinyl tapes, desiccants, insect repellents, fragrances, surgical masks, bearings, carrots, cucumbers, eggplants, mushrooms,

other Japanese confectionery, western confectionery, fishery products, frozen foods, daily necessities, toys, various industrial products, agricultural products, etc.

Specification

-

Body width

Standard / Wide

-

End system

Multi Motion / Rotary Cutter

-

Representative model

[Standard・Multi Motion]

7072V2[Wide・Multi Motion]

7272V2[Standard・Rotary Cutter]

7001V2[Wide・Rotary Cutter]

7004V2 -

Packaging capacity

[7072V2] 10〜270rpm

[7272V2・7001V2] 10〜150rpm

[7004V2] 10〜300rpm

-

Packaging film size

[7072V2]

Max Film Width 450mm/Max Bag Folding Diameter 210mm/Max Roller Diameter 320mm -

Packaging product dimensions

[7072V2]

Max Width 200mm/Max Height 120mm -

Machine dimensions

[7072V2]

(W)980mm×(H)1,460mm×(L)4,680mm -

Weight of machine

[7072V2]

1,200kg -

Power consumption

3phases 200V 4KW 20A

-

Air consumption

0.5MPa Approx.100NL/min

-

Option

Adjustable Former・Hold Down Conveyor・Full Pack・Date Printer ・Print Inspection・Gas Flushing・Creasing device・End seal Folding device・Attachless conveyor・ Others

-

Annotation

Machine specifications and packaging capabilities depend on product shape and characteristics, and film material. Please contact us.

Product category:Horizontal Packaging Machine

KBF-7000V Horizontal Packaging Machine

It is a high spec top load horizontal packaging machine which realized certain packaging with new mechanism.

It has fixed film winding position style and sanitary structure for easy use and maintanance.

Product features

-

01

Installation of a new mechanism with higher functionality and higher reliability

Stable film feeding and more reliable sealing have been realized. Multi-motion sealing enables tight sealing to suit film and product shapes.

-

02

Pursue ease of use

Stable film feeding and more reliable sealing have been realized. Multi-motion sealing enables tight sealing to suit film and product shapes.

-

03

Hygienic and easy-to-maintain structure

Use of stainless steel covers improves sanitary performance. We have made the cover largely transparent and made it visible so that we can check the operating conditions inside it. We also focused on daily maintenance such as easy installation and removal of the supply belt.

Purpose

Cookies, sauces, biscuits, confectionery breads, chocolates (including chocolates), candies, ramney, roasted rice cake, oaks, bunkers, tempura, frozen hamburgers, frozen gyosa, frozen shomei, vinyl tapes, desiccants, insect repellents, fragrances, surgical masks, bearings, carrots, cucumbers, eggplants, mushrooms, other Japanese confectionery, western confectionery, fishery products, frozen foods, daily necessities, toys, various industrial products, agricultural products, etc.

Specification

-

Body width

Standard / Wide

-

End system

Multi Motion / Rotary Cutter

-

Representative model

[Standard・Multi Motion]

7072V[Wide・Multi Motion]

7272V[Standard・Rotary Cutter]

7001V[Standard・Rotary Double Cutter]

7004V -

Packaging capacity

[7072V/] 10〜250rpm

[7272V/7001V] 10〜150rpm

[7004V] 10〜300rpm -

Packaging film size

[7072V]

Max Film Width 450mm/Max Bag Folding Diameter 210mm/Max Roller Diameter 320mm[7272V]

Max Film Width 650mm/Max Bag Folding Diameter 310mm/Max Roller Diameter 320mm[7001V/7004V]

Max Film Width 370mm/Max Bag Folding Diameter 170mm/Max Roller Diameter 320mm -

Packaging product dimensions

[7072V]

Max Width 200mm/Max Height 120mm[7272V]

Max Width 300mm/Max Height120mm[7001V/7004V]

Max Width 160mm/Max Height40mm -

Machine dimensions

[7072V]

(W)1,013mm×(H)1,522mm×(L)4,510mm[7272V]

(W)1,163mm×(H)1,522mm×(L)4,510mm[7001V]

(W)893mm×(H)1,522mm×(L)4,144mm -

Weight of machine

[7072V]

1,200kg[7272V]

1,500kg[7001V]

1,000kg -

Power consumption

3phases 200V/20A/4KW

-

Air consumption

0.5MPa Approx.100NL/min

-

Standard equipment

Adjustable Former・Hold Down Conveyor

-

Option

Full Pack・Date Printer ・Print Inspection・Gas Flushing・Creasing device・End seal Folding device・Attachless conveyor・ Others

-

Annotation

Machine specifications and packaging capabilities depend on product shape and characteristics, and film material. Please contact us.

Product category:Horizontal Packaging Machine

KBF-7500V Horizontal Packaging Machine – Film bottom load

It is a high spec bottom load horizontal packaging machine which realized certain packaging with new mechanism.

It has film winding fixed position style and sanitary structure for easy use and maintanance.

Product features

-

01

Installation of a new mechanism with higher functionality and higher reliability

Stable film feeding and more reliable sealing have been realized. Multi-motion sealing enables tight sealing to suit film and product shapes.

-

02

Pursue ease of use

We have realized a low-position winding style that is friendly to the operator. With the panel computer, the model can be easily changed and set.

-

03

Hygienic and easy-to-maintain structure

The use of stainless steel covers has improved sanitary performance. We have made the cover largely transparent and made it visible so that we can check the operating conditions inside it. We also focused on daily maintenance such as easy installation and removal of the supply belt.

Purpose

Confectionery,Buns,Tube‐Shaped Fish Paste Cake,Industrial Products,Chinese Chive, Green Onion, Burdock, Carrot,Spinach, Leaf Ginger, Honewort, ,Dried Noodles, Cheese, Bean‐Starch Vermicelli,Rubber Gloves, Surgical Masks

Specification

-

Body width

Standard / Wide

-

End system

Multi Motion / Rotary Cutter

-

Model name

[Standard・Multi Motion]

7572V[Wide・Multi Motion]

7772V[Standard・Rotary Cutter]

7501V[Standard・Rotary Double Cutter]

7504V -

Packaging capacity

[7572V] 10〜250rpm

[7772V/7501V] 10〜150rpm

[7504V] 10〜300rpm -

Packaging film size

[7572V]

Max Flm Width 450mm/Max Bag Folding Diameter 210mm/Max Rroller Diameter 350mm[7772V]

Max Flm Width 650mm/Max Bag Folding Diameter 310mm/Max Rroller Diameter 350mm[7501V/7504V]

Max Flm Width 370mm/Max Bag Folding Diameter 170mm/Max Rroller Diameter 350mm -

Packaging product dimensions

[7572V]

Max Width 200mm/Max Height 120mm[7772V]

Max Width 300mm/Max Height120mm[7501V/7504V]

Max Width 160mm/Max Height40mm -

Machine dimensions

[7572V]

(W)1,013mm×(H)1,490mm×(L)5,160mm[7772V]

(W)1,173mm×(H)1,490mm×(L)5,160mm[7501V]

(W)893mm×(H)1,490mm×(L)4,794mm -

Weight of machine

[7572V]

1,500kg[7772V]

1,800kg[7501V]

1,100kg -

Power consumption

3phases 200V 4KW 20A

-

Air consumption

0.5MPa Apprx.100NL/min

-

Standard equipment

Adjustable Former・Hold Down Conveyor

-

Option

Full Pack・Date Printer ・Print Inspection・Gas Flushing・Creasing device・End seal Folding device・Attachless conveyor・ Others

-

Annotation

Machine specifications and packaging capabilities depend on product shape and characteristics, and film material. Please contact us.

Product category:Horizontal Packaging Machine

KBF-700e Horizontal Packaging Machine

Compact size and easy to use.

Small but high performance.

It is a compact size top load horizontal packaging machine.

Product features

-

01

High Specification in Compact Body

Max. 120 bgs/min(Box Motion) is achievable. High quality Micro-computer with many functions is applied on newly designed compact body.

-

02

Easy mainteannce in compact body

Mechanical drive and transmission parts are centerized for easy maintenance.

Trash down construction is equipped. Stainless steel chute is equipped at main body bottom and end seal section, so that trash/dust is not remained inside of body for sanitary and cleaning. -

03

Operator Friendly

Stainless steel cover is applied. Maintenance and sanitary is substantially improved.Color touch panel is applied. Operation and setting is easier than ever.Date coder position is changed to lower for more easy change over and setting.See-through cover is applied at the center sealing section. It enables for operator to check the film flow visually.

Purpose

Cookies, Sable, Biscuit, Buns, Chocolate, Candy, Lemon-lime, Rice Cracker, Manju, Tempura, Frozen Hamburger, Frozen Meat Dumpling, Frozen Shaomai, Plastic Tape, Desiccant, Mothball, Air Freshener, Surgical Mask, Bearing, Carrot, Cucumber, Eggplant, Shimeji Mushroom, Enoki Mushroom

Other Confectionery ProductProducts, Fishery Products, Frozen Foods, Conveniene Goods, Toys, Industrial Products, Agricultural Products etc.

Specification

-

Type

type-S/type-SS

-

End system

Box Motion/Rotary Cutter

-

Representative model

[type-SS/type-S・Box Motion]

701eb/702eb[type-S/type-M・Rotary Cutter]

701e/702e[type-S/type-M・Rotary Double Cutter]

704e/705e -

Packaging capacity

[701eb] 10〜120rpm

[702eb] 10〜100rpm

[701e/702e] 10〜180rpm

[704e/705e] 10〜360rpm -

Packaging film size

Max Flm Width 450mm/Max Bag Folding Diameter 210mm/Max Rroller Diameter 300mm

-

Packaging product dimensions

[701eb]

Max Width 200mm/Max Height 65mm[702eb]

Max Width 200mm/Max Height 90mm[701e/704e]

Max Width 200mm/Max Height 40mm[702e/705e]

Max Width 200mm/Max Height 60mm -

Machine dimensions

[701eb/702eb]

(W)993mm×(H)1,436mm×(L)3,130mm[701e/704e]

(W)961mm×(H)1,436mm×(L)3,130mm -

Weight of machine

950kg

-

Power consumption

3phases 200V 20A 4KW

-

Air consumption

0.5MPa Apprx.100NL/min

-

Option

Adjustable Former・Hold Down Conveyor・Full Pack・Date Printer ・Print Inspection・Gas Flushing・Creasing device・End sealFolding device・Attachless conveyor・ Others

-

Annotation

Machine specifications and packaging capabilities depend on product shape and characteristics, and film material. Please contact us.

Product category:Horizontal Packaging Machine

KBF-750e Horizontal Packaging Machine -Film Bottom Load-

Compact size and easy to use.

Small but high performance.

It is a compact size bottom load horizontal packaging machine.

Product features

-

01

High Specification in Compact Body

Max.120 bgs/min(Box Motion) is achievable. High quality Micro-computer with many functions is applied on newly designed compact body.

-

02

Easy mainteannce in compact body

Mechanical drive and transmission parts are centerized for easy maintenance.

Trash down construction is equipped. Stainless steel chute is equipped at main body bottom and end seal section, so that trash/dust is not remained inside of body for sanitary and cleaning. -

03

Operator Friendly

Stainless steel cover is applied. Maintenance and sanitary is substantially improved.

Color touch panel is applied. Operation and setting is easier than ever.

Date coder position is changed to lower for more easy change over and setting.

See-through cover is applied at the center sealing section. It enables for operator to check the film flow visually. -

04

The LED informs the product supply position.

The LED indicator informs the product feed position with the optional feed guide lamp. This is best suited to the specifications for directly supplying products to transparent plain films.(Patented)

Purpose

Sticky Confectioneries(Dorayaki, Steamed Manju, Skewered Dumplings, Rice Cake Confectionery, Pound Cake etc)

Bulk Products (Cookies, Rice Cracker etc.)

Raw Meat, Fish Fillet, Noodles, Pastes, Surgical Masks, etc.

Specification

-

End system

Box Motion/Rotary Cutter

-

Representative model

[type-SS/type-S・Box Motion]

751eb/752eb[type-S/type-M・Rotary Cutter]

751e/752e[type-S/type-M・Rotary Double Cutter]

754e/755e -

Packaging capacity

[751eb] 10〜120rpm

[752eb] 10〜100rpm

[751e/752e] 10〜180rpm

[754e/755e] 10〜360rpm -

Packaging film size

Max Flm Width 450mm/Max Bag Folding Diameter 210mm/Max Rroller Diameter 300mm

-

Packaging product dimensions

[751eb]

Max Width 200mm/Max Height 65mm[752eb]

Max Width 200mm/Max Height 90mm[751e/754e]

Max Width 200mm/Max Height 40mm[752e/755e]

Max Width 200mm/Max Height 60mm -

Machine dimensions

[751eb/752eb]

(W)993mm×(H)1,259mm×(L)2,700mm[751e/754e]

(W)961mm×(H)1,259mm×(L)2,700mm -

Weight of machine

950kg

-

Power consumption

3phases 200V 20A 4KW

-

Air consumption

0.5MPa Apprx.100NL/min

-

Option

Supply guide lamp (patented)・Adjustable Former・Hold Down Conveyor・Full Pack・Date Printer ・Print Inspection・GasFlushing・Creasing device・End seal Folding device・ Others

-

Annotation

Machine specifications and packaging capabilities depend on product shape and characteristics, and film material. Please contact us.

Product category:Horizontal Packaging Machine

GW-7 Horizontal Packaging Machine

New compact pillow packaging machine with square-folding function.

Award history

-

- Fiscal 2013 (2013) Received the JapanpackAwards2013 Chairman's Award, sponsored by the Japan Packaging Machinery Association

Product features

-

01

Compact but diverse functions

Though it is compact size, it has various standard function such as creasing device, upper holding brush, gusset device, folding device.

The installation size is smaller than our Model GW-4K which saves the layout space.

It can have contamination protection,insect proof, ageless insurting, N2 gas flushing. -

02

User friendly operability

The attachless conveyor in the production feeding part enables to feed the product with discretion.

Color touch panel enables to operate easiler. -

03

Easy maintainance structure

Large clear plastic cover enables to see the inside of the machine.Feeding belt can be easily detached which makes the cleaning also easy.SUS cover and the structure of the tray&chute inside the machine makes it hygienic.

Purpose

Manju, Dorayaki, Bouche, Sponge Cake, Surgical Mask, etc.

Specification

-

Packaging capacity

5〜60rpm

-

Packaging film size

Max Flm Width 320mm/Max Bag Folding Diameter 150mm/Max Rroller Diameter 300mm

-

Cut pitch

Max 160mm

-

Packaging product dimensions

Max Width120mm/Max Height 50mm

-

Machine dimensions

(W)848mm×(H)1,466mm×(L)1,750mm

-

Weight of machine

700kg

-

Power consumption

3phases 200V 4KW 20A

-

Air consumption

0.5Mpa Apprx.210NL/min

※60rpm in empty bag forming operation -

Standard accessory

Creasing Device,Overhead hold down brush,Gusset Device,Folding Device

-

Option

Gas Flushing Device ,Bite Forecast,Pin Hole Roller,Sachet attach roller,Pre-seal,Date Printer,Print Inspection Device

-

Annotation

Machine specifications and packaging capabilities depend on product shape and characteristics, and film material. Please contact us.

Product category:Horizontal Packaging Machine

KBF-74000ZⅡ Four side seal zipper packaging machine

It is a horizontal four-side seal zipper Packaging machine excellent in beautiful packaging and size change.

Product features

-

01

High performance

100rpm possible with a zipper package.Good operability, maintenance performance.

-

02

Good convertibility

As the convertible size is wide range, applicable for the later product change.Easy to replace the unit for die-roll cutter spec.

-

03

Reliable packaging

For a secure sealant, BOX motion type is used for end seal part.To enable the beautiful package looking, it trims the gap of film caused by miss alignment.

-

04

Do not send out the NG product

It equips the function to auto discharge the NG package product.To protect the product inside the package, it will auto discharge without sealing or cutting.

Purpose

Products that requires rePackaging after use, such as plaster, transdermal medicine and seaweed

Specification

-

Packaged goods

Plaster, Surgical Mask, etc.

-

Packaging capacity

10〜100rpm

-

Wrapping film width

195〜460mm/ Max Roller Diameter 300mm

-

Packaging finish width

(Zipper Application) 120〜215mm/(Without Zipper)83〜215mm

-

Cut pitch

(Zipper Application)100〜160mm/(Without Zipper)80〜999mm

-

Packaging form

Four side fin seal Packaging,Four side fin seal Packaging with Zipper(Convertible)

-

Packaging bag size

(W)53〜145mm×(H)Max 18mm×(L)60〜900mm

-

Packaging materials

Various laminate films

-

Machine dimensions

(W)1,240mm×(H)1,673mm×(L)7,930mm

-

Weight of machine

Approx.3,000kg

-

Power consumption

3phases AC200V 40A

-

Air consumption

0.5MPa Apprx.100NL/min

-

Standard accessory

Film Roll Holder Brake Auto Adjustment,Side Sealer Unit Auto Adjustment (Up/Dwon, and width),Auto end sealer position adjuster,Infeed・Film・End sealer・Cutter Timing Auto adjsutmentt,Touch Panel,Product Code 99 memories,Auto Splicer with auto discharge,Damper Type Reject Conveyor,Full Pack(In no active, Empty bag reject Function),Auto reject of start up,End Seal Bite Forecast (Auto reject withtout seal),Splice tape detect (Auto Reject.),Zipper tape splice detect.(Auto Reject),End seal bite detect(Auto reject by no cut),Zipper seal fault detect.Film short alarm ,Zipper tape short alarm,Selfdiagnostice Function(Micom・Servo motor・Heater,Triming tape fault detect.,Photo sensor,Photo sensor sensitivity adjustment(Color auto changing),Film holder Auto-centering,Infeed coveyor pitch changable,Infeed Overload detect(Machine Stop)

-

Accessories

Reject discarge case・Triming tape discharge case.

-

Option

Corner R shape cut(Die roll cutter・Unit replace type),Film Roll Lifer,Date Printer,Print Inspection Machine,Auto feeding system,Triming tape winding device(In case of, easy static film),Film up/dewn position detect,I notch cut

[Pentagon Notch ]

・Pentagon Notch (Width2mm Depth2.5mm)

・Bag Width 125〜215mm

・Cut Pitch 120〜160mm[φ8mm Hole Punch]

・Side deal Width20mm At the center

・Bag Width 145〜215mm

・Cut Pitch 120〜160mm -

Annotation

Packaging capacity varies depending on the products and the film.Please contact us.

- 01 Vertical Packaging Machine

-

KBF-6000UXR Vertical pillow packaging machine KBF-6000UX Vertical pillow packaging machine KBF-6000X Vertical Packaging Machine KBF-6000XR High Speed Vertical Packaging Machine KBF-6000Xe Vertical Packaging Machine KBF-6000XeD Vertical Packaging Machine KBF-6000XeR High Speed Vertical Packaging Machine KBF-6000XG Vertical Packaging Machine

- 02 Horizontal Packaging Machine

-

KBF-7000V2 Horizontal Form Fill Seal Machine KBF-7000V Horizontal Packaging Machine KBF-7500V Horizontal Packaging Machine – Film bottom load KBF-700e Horizontal Packaging Machine KBF-750e Horizontal Packaging Machine -Film Bottom Load- GW-7 Horizontal Packaging Machine KBF-74000ZⅡ Four side seal zipper packaging machine

- 03 Overwrapping Machine

- 04 Auto-Caser

- 05 Cup Filling And Capping System